Fabricante de flanges DIN 86037

OEM de acordo com seu desenho, melhor preço.

Material | CuNi90/10 ,CuNi70/30,C70600,C71500 |

Tamanho | DN15 a DN810 |

Classificação de pressão | 10Bra,16Bar |

Embalagem | Estojo de madeira resistente à água do mar |

Padrão | DIN86037 |

sales@copperry.com

OEM de acordo com seu desenho, melhor preço.

Material | CuNi90/10 ,CuNi70/30,C70600,C71500 |

Tamanho | DN15 a DN810 |

Classificação de pressão | 10Bra,16Bar |

Embalagem | Estojo de madeira resistente à água do mar |

Padrão | DIN86037 |

A COPPERRY pode produzir o material do flange interno do cuni CuNi10Fe1.6Mn e CuNi30Fe1.0Mn para seu projeto.

Material: A105 (galvanizado por imersão a quente), 316L, liga de alumínio. O flange externo é feito de liga de alumínio porque é leve e resistente à corrosão da água do mar.

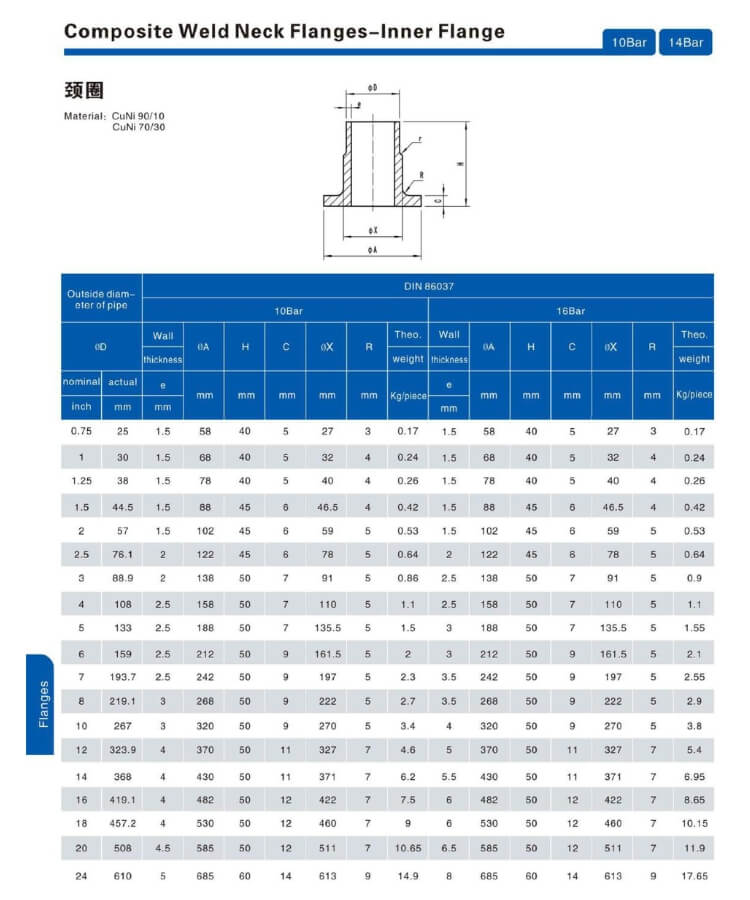

Os flanges DIN86037 consistem em um flange interno de cobre-níquel e um flange externo de aço carbono. O vídeo a seguir mostra o flange interno DIN86037 acabado.

A COPPERRY fabrica flanges DIN86037 há 20 anos. Desde o forjamento em branco de flanges DIN86037, recozimento, CNC e inspeção de produtos, para fornecer a você produtos garantidos.

1, Nosso flange interno de cobre e níquel padrão DIN86037, ou colar de cobre e níquel, é feito de forjamento. Algumas fábricas optam pela fundição para reduzir o custo.

2, cada flange interno de cobre e níquel é embalado individualmente em uma caixa personalizada para evitar danos.

3、Produtos de acordo com os requisitos da marcação, exibindo o logotipo de sua empresa.

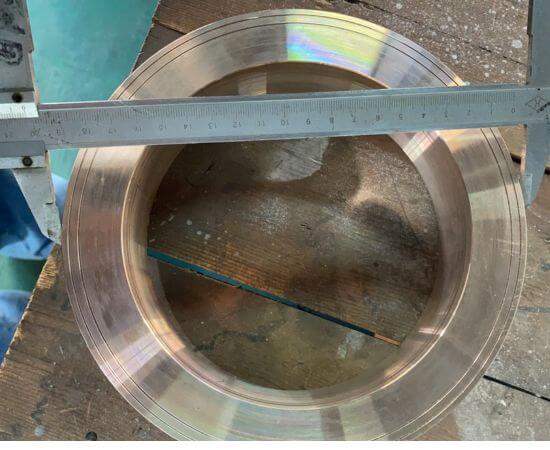

Nosso cliente fez o pedido do flange interno din86037 e veio pessoalmente à nossa empresa para inspeção.

Os clientes usam calibradores vernier para medir a altura, a espessura da parede e as dimensões do diâmetro externo do flange cuni din86037. As dimensões medidas pelo cliente de nosso produto correspondem exatamente ao desenho.

Nossa empresa fornece aos clientes espectrômetros importados da Alemanha. O cliente testa a composição química de cada especificação de flanges din86037, que atende aos requisitos da norma cuni90/10.

O cliente pesa o flange cuni padrão din86037 de pequeno a grande porte em uma balança eletrônica.

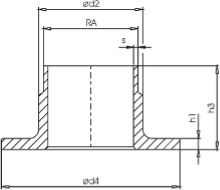

RA em nominal | RA mm OD | s mm | d2 mm | d4 mm | h3 mm | h1 mm | peso kg/peça |

1/2 | 20 | 1,0 | 21 | 45 | 40 | 5 | 0,13 |

3/4 | 25 | 1,5 | 27 | 58 | 40 | 5 | 0,15 |

1 | 30 | 1,5 | 32 | 68 | 40 | 5 | 0,20 |

1 1/4 | 38 | 1,5 | 40 | 78 | 40 | 5 | 0,25 |

1 1/2 | 44,5 | 1,5 | 46,5 | 88 | 45 | 6 | 0,36 |

2 | 57 | 1,5 | 59 | 102 | 45 | 6 | 0,45 |

2 1/2 | 76 | 2,0 | 78 | 122 | 45 | 6 | 0,62 |

3 | 89 | 2,0 | 91 | 138 | 50 | 7 | 0,86 |

4 | 108 | 2,5 | 110 | 158 | 50 | 7 | 1,10 |

5 | 133 | 2,5 | 135,5 | 188 | 50 | 7 | 1,50 |

6 | 159 | 2,5 | 161,5 | 212 | 50 | 9 | 2,00 |

7 | 194 | 3,0 | 197 | 242 | 50 | 9 | 2,30 |

8 | 219 | 3,0 | 222 | 268 | 50 | 9 | 2,70 |

10 | 267 | 3,0 | 270 | 320 | 50 | 9 | 3,40 |

12 | 324 | 4,0 | 327 | 370 | 50 | 11 | 4,60 |

14 | 368 | 4,0 | 371 | 430 | 50 | 11 | 6,30 |

16 | 419 | 4,0 | 422 | 482 | 50 | 12 | 7,50 |

18 | 457 | 4,5 | 460 | 530 | 50 | 12 | 9,10 |

20 | 508 | 5,0 | 511 | 585 | 50 | 12 | 10,70 |

24 | 610 | 5,0 | 613 | 685 | 60 | 14 | 14,90 |

28 | 711 | 6,0 | 714 | 800 | 60 | 14 | 21,00 |

32 | 813 | 6,0 | 816 | 905 | 60 | 14 | 24,50 |

36 | 914 | 8,0 | 918 | 1000 | 60 | 14 | 29,20 |

40 | 1016 | 8,0 | 1018 | 1110 | 60 | 14 | 34,00 |

COPPERRY Com mais de 20 anos de fabricação, somos especialistas líderes do setor na produção de flanges DIN86037. Atendemos a vários estaleiros na China e em todo o mundo.

O flange interno de cobre-níquel foi projetado para proteção contra a corrosão da água do mar. Garantindo longa vida útil e desempenho confiável.

Ele é tratado com um processo de galvanização por imersão a quente para protegê-lo do ar salgado a bordo, o que acelera o processo de enferrujamento.

O flange interno DIN86037 e o flange externo de aço galvanizado por imersão a quente são firmemente fixados com parafusos, criando uma vedação superior. O flange DIN 86037 oferece uma solução eficiente, durável e econômica para os requisitos de construção naval. prometem não apenas qualidade e desempenho, mas também a garantia de longevidade.

Os flanges DIN86037 são mais baratos do que os flanges de pescoço alto de cobre e níquel. Os flanges DIN86037 são flanges de encaixe solto, o flange externo pode ser girado, você pode instalar facilmente o flange no local.

Recomenda-se que o flange din86037 seja equipado com um revestimento isolante. O flange interno de níquel-cobre e o flange externo de aço carbono são dois metais. O contato entre dois metais diferentes produzirá corrosão por diferença de potencial.

ps: a corrosão por diferença de potencial é mais grave do que a corrosão por água do mar.

Podemos responder inequivocamente que nosso flange interno CuNi10Fe1.6Mn é feito de forjamento de barra sólida.

Não usamos fundição para fabricar o flange interno CuNi10Fe1.6Mn. O flange fundido tem orifícios de ar e não é suficientemente rígido. Isso leva a vazamentos e corrosão grave durante o uso real.

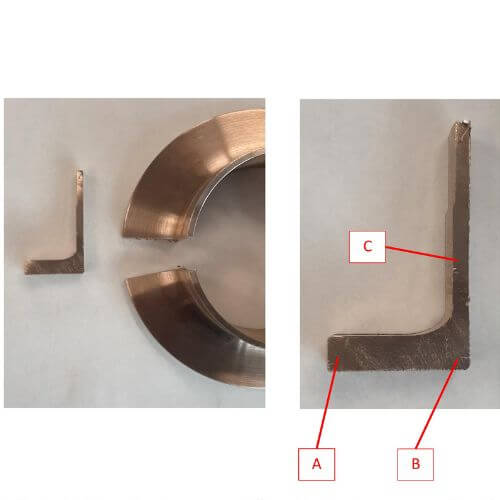

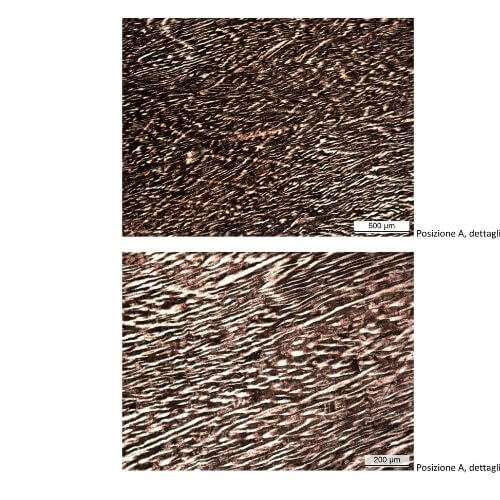

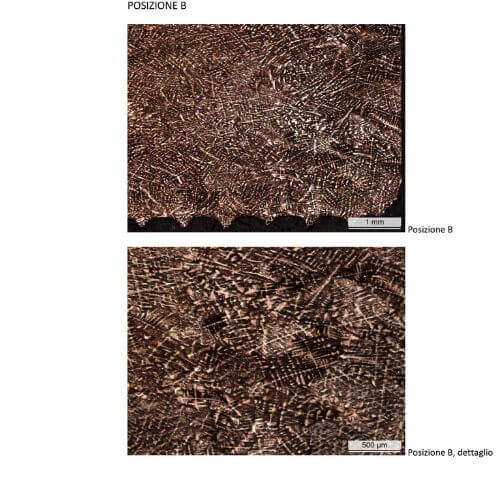

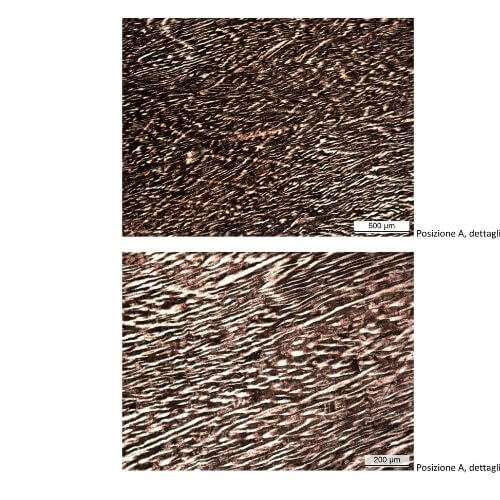

Abaixo está a foto da análise metalográfica do flange interno de CuNi10Fe1.6Mn fundido.

Você pode ver os defeitos no flange de CuNi10Fe1.6Mn fundido na imagem abaixo.

Preparação da análise metalográfica do flange CuNi

A, B, C, três pontos para fazer a análise metalográfica

Os cristais dendríticos, com os cristais alongados, são indicados no estado de fundição.

Estrutura claramente fundida com orientação cristalina desordenada e caótica.

Há buracos de ar e impurezas, sem forjamento.