DIN 86037 flange manufacturer

OEM as per your drawing, best price.

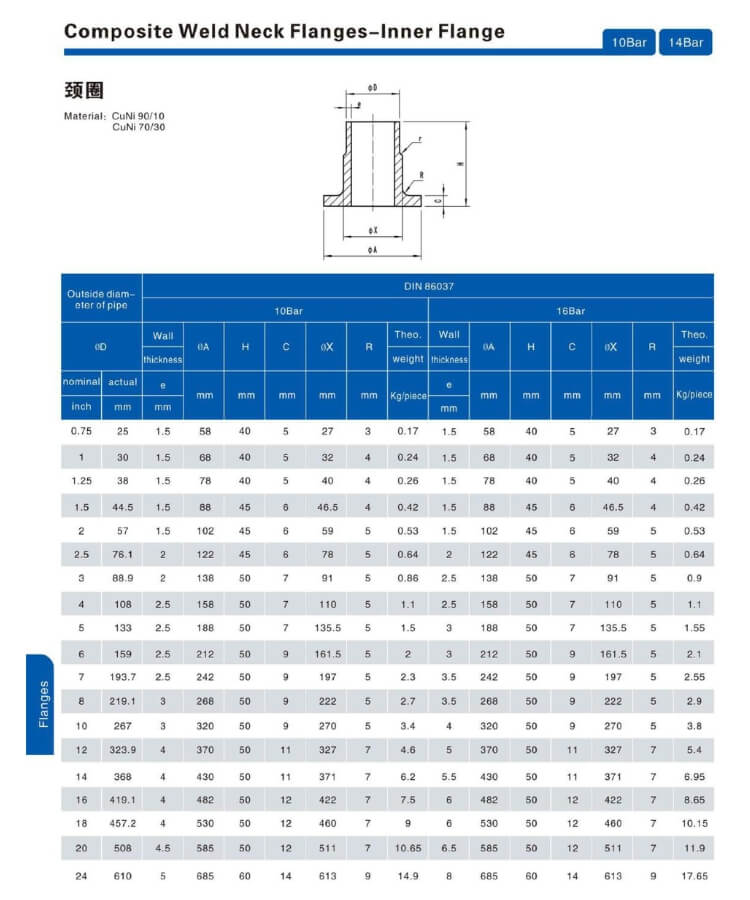

Material | CuNi90/10 ,CuNi70/30,C70600,C71500 |

Size | DN15 to DN810 |

Pressure Rating | 10Bra,16Bar |

Packaging | Seaworthy Wooden Case |

Standard | DIN86037 |

sales@copperry.com

OEM as per your drawing, best price.

Material | CuNi90/10 ,CuNi70/30,C70600,C71500 |

Size | DN15 to DN810 |

Pressure Rating | 10Bra,16Bar |

Packaging | Seaworthy Wooden Case |

Standard | DIN86037 |

COPPERRY can produce the cuni inner flange material CuNi10Fe1.6Mn and CuNi30Fe1.0Mn for your project.

Material: A105 (hot-dip galvanized), 316L, aluminum alloy. The outer flange is made of aluminum alloy because it is lightweight and resistant to seawater corrosion.

DIN86037 flanges consist of a copper nickel inner flange and carbon steel outer flange.The following video shows you the finished DIN86037 inner flange.

COPPERRY has been manufacturing DIN86037 flanges for 20 years. From DIN86037 flange blank forging, annealing, CNC, product inspection, to provide you with assured products.

1, Our DIN86037 standard copper nickel inner flange, or copper nickel collar, is made of forging. Some factories choose casting to reduce cost.

2, Each copper nickel inner flange is individually packaged in a customized carton to prevent damage.

3、Products in accordance with the requirements of the marking, playing your company logo.

Our customer din86037 inner flange order, the customer personally came to our company for inspection.

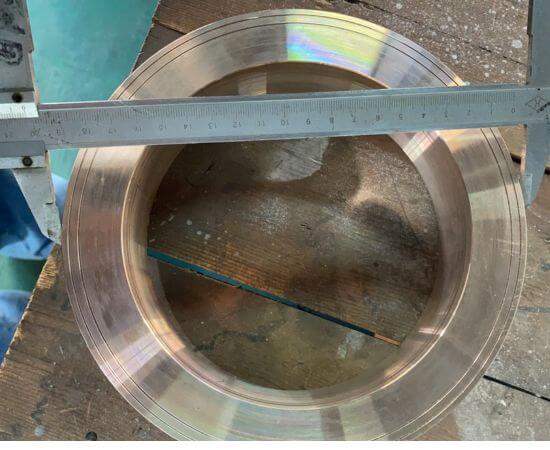

Customers use vernier calipers to measure the height, wall thickness, and outside diameter dimensions of din86037 cuni flange. the dimensions measured by the customer of our product match exactly with the drawing.

Our company provides customers with spectrometers imported from Germany. The customer tests the chemical composition of each specification of din86037 flanges, which meets the requirements of the standard for cuni90/10.

The customer weighs din86037 standard cuni flange from small to large on an electronic scale.

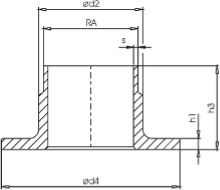

RA in nominal | RA mm OD | s mm | d2 mm | d4 mm | h3 mm | h1 mm | weight kg/piece |

1/2 | 20 | 1,0 | 21 | 45 | 40 | 5 | 0,13 |

3/4 | 25 | 1,5 | 27 | 58 | 40 | 5 | 0,15 |

1 | 30 | 1,5 | 32 | 68 | 40 | 5 | 0,20 |

1 1/4 | 38 | 1,5 | 40 | 78 | 40 | 5 | 0,25 |

1 1/2 | 44,5 | 1,5 | 46,5 | 88 | 45 | 6 | 0,36 |

2 | 57 | 1,5 | 59 | 102 | 45 | 6 | 0,45 |

2 1/2 | 76 | 2,0 | 78 | 122 | 45 | 6 | 0,62 |

3 | 89 | 2,0 | 91 | 138 | 50 | 7 | 0,86 |

4 | 108 | 2,5 | 110 | 158 | 50 | 7 | 1,10 |

5 | 133 | 2,5 | 135,5 | 188 | 50 | 7 | 1,50 |

6 | 159 | 2,5 | 161,5 | 212 | 50 | 9 | 2,00 |

7 | 194 | 3,0 | 197 | 242 | 50 | 9 | 2,30 |

8 | 219 | 3,0 | 222 | 268 | 50 | 9 | 2,70 |

10 | 267 | 3,0 | 270 | 320 | 50 | 9 | 3,40 |

12 | 324 | 4,0 | 327 | 370 | 50 | 11 | 4,60 |

14 | 368 | 4,0 | 371 | 430 | 50 | 11 | 6,30 |

16 | 419 | 4,0 | 422 | 482 | 50 | 12 | 7,50 |

18 | 457 | 4,5 | 460 | 530 | 50 | 12 | 9,10 |

20 | 508 | 5,0 | 511 | 585 | 50 | 12 | 10,70 |

24 | 610 | 5,0 | 613 | 685 | 60 | 14 | 14,90 |

28 | 711 | 6,0 | 714 | 800 | 60 | 14 | 21,00 |

32 | 813 | 6,0 | 816 | 905 | 60 | 14 | 24,50 |

36 | 914 | 8,0 | 918 | 1000 | 60 | 14 | 29,20 |

40 | 1016 | 8,0 | 1018 | 1110 | 60 | 14 | 34,00 |

COPPERRY With 20+ years of manufacturing, we are industry-leading specialists in producing DIN86037 flanges. Having served numerous shipyards across China and worldwide.

The copper-nickel inner flange is designed for protection against seawater corrosion. Ensuring long service life and reliable performance.

It is treated with a hot-dip galvanizing process to shield it from the salty air onboard, to hasten the rusting process.

DIN86037 inner flange and the hot-dip galvanized steel outer flange – are securely fastened with bolts, creating a superior seal. DIN 86037 flange offers an efficient, durable, and cost-effective solution for shipbuilding requirements. promise not only quality and performance but also the guarantee of longevity.

DIN86037 flanges are cheaper than copper nickel high neck flanges. DIN86037 flanges are loose-fitting flanges, the outer flange can be rotated , you can easily install the flange on site.

The din86037 flange is recommended to be fitted with an insulating liner. Copper nickel inner flange and carbon steel outer flange are two metals. Contact between two different metals will produce potential difference corrosion.

ps: potential difference corrosion is more serious than seawater corrosion.

We can answer unequivocally that our CuNi10Fe1.6Mn inner flange is made from solid bar forging.

We firmly do not use casting to make CuNi10Fe1.6Mn inner flange. Because the casting flange has air holes and is not hard enough. It leads to leakage and serious corrosion during actual use.

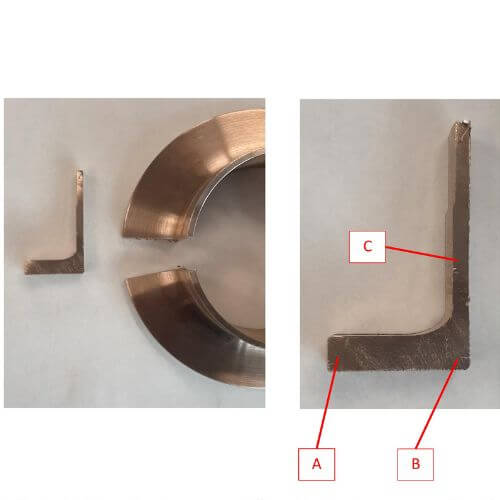

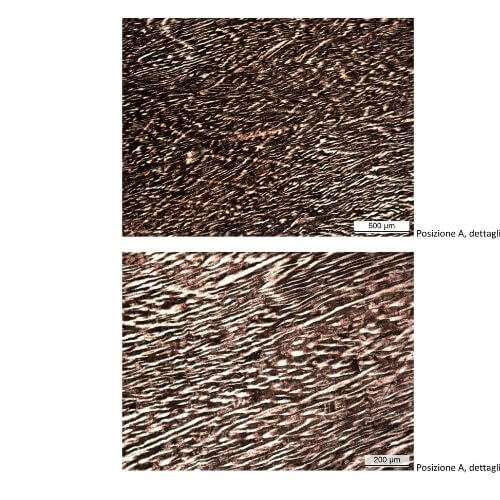

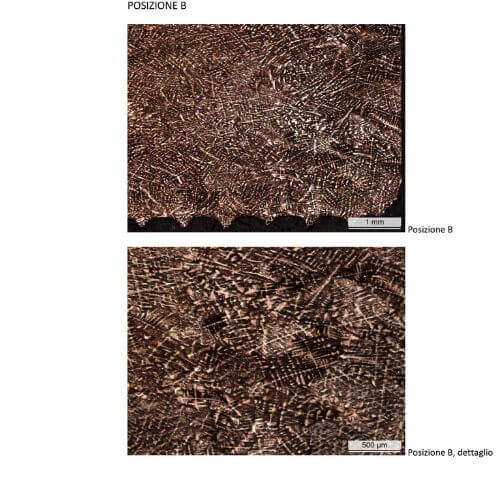

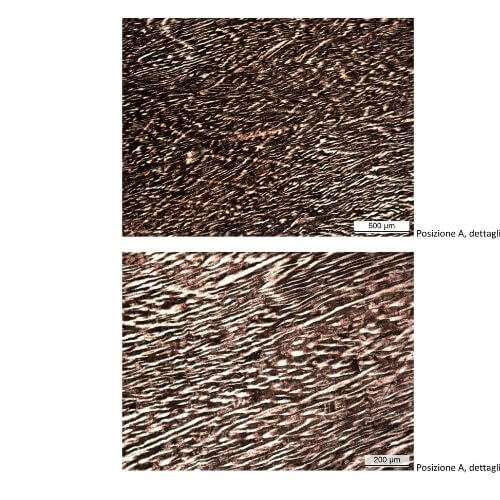

Below shows you the photo of metallographic analysis of cast CuNi10Fe1.6Mn inner flange.

You can see the defects in the cast CuNi10Fe1.6Mn flange in the picture below.

CuNi Flange Metallographic Analysis Preparation

A, B, C, three points to do metallographic analysis

Dendritic crystals, the crystals being elongated, are indicated in the Casting state.

Clearly cast structure with disordered and chaotic crystal orientation.

There are air holes and impurities, no forging.