sales@copperry.com

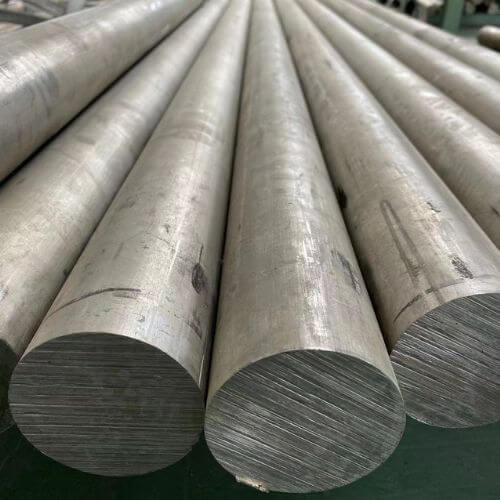

Explore our high-quality copper nickel bars for various industries, featuring top-grade materials, durability, and exceptional performance.

A copper nickel bar typically consists of copper and nickel, with small amounts of other elements such as manganese, iron, and zinc to enhance specific properties.

Copper nickel bars are metal bars made from copper nickel alloys. They are commonly used in industrial applications due to their high corrosion resistance, thermal and electrical conductivity, and durability.

Copper nickel bars are generally non-magnetic, as both copper and nickel are non-ferromagnetic materials.

Quality can be determined by checking for certifications, such as ISO or ASTM standards, and by ensuring that the alloy composition meets the required specifications for its intended application.

Yes, copper nickel bars can be recycled, making them an eco-friendly choice for industries looking to minimize their environmental impact.

There are indeed various grades of copper nickel bars, with each grade offering specific properties suited for different applications. Some common grades include CuNi10Fe1Mn, CuNi30Mn1Fe, and CuNi90/10.

The price of copper nickel bars can vary depending on factors such as the alloy’s grade, size, and market conditions. It’s best to consult with suppliers for the most up-to-date pricing information.

Copper nickel bars are used in various industries, including marine, oil and gas, power generation, desalination, and more. They are used in applications such as shipbuilding, offshore oil and gas platforms, heat exchangers, condensers, and electrical components.

To order copper nickel bars, contact a reputable manufacturer or supplier and provide them with your specific requirements and specifications. The manufacturer or supplier will provide you with a personalized quote and delivery estimate.

Copper nickel bars should be stored in a dry, clean, and well-ventilated area to prevent corrosion. They should be stored away from sources of moisture and heat, and should be protected from contact with other metals to prevent galvanic corrosion.

Copper nickel bars are easy to machine and can be cut, drilled, and welded using standard equipment and techniques. However, due to their high strength and toughness, special care should be taken to avoid tool chatter and overheating.

Copper nickel bars are easy to machine and can be cut, drilled, and welded using standard equipment and techniques. However, due to their high strength and toughness, special care should be taken to avoid tool chatter and overheating.