CuNi Pipe Manufacturers in china

| Type | CuNi90/10 CuNi70/30 |

| Size | 10mm to 810mm |

| Applications | Seaweter systems |

| Standard | DIN 86019,EEMUA 234 |

We have been supplying cuni pipes for FPSO,Tugboat,LNG,Navy for 20 years,you can trust us.

sales@copperry.com

| Type | CuNi90/10 CuNi70/30 |

| Size | 10mm to 810mm |

| Applications | Seaweter systems |

| Standard | DIN 86019,EEMUA 234 |

We have been supplying cuni pipes for FPSO,Tugboat,LNG,Navy for 20 years,you can trust us.

we supply cuni pipes are certified by CCS, DNV-GL, and BV classification societies.cuni pipes are 6 metres/pc in length and are packed in plastic bags.

The cuni pipe production lead time is 45 days. If cuni pipe you desperately need we have in stock. Before the cuni pipe is shipped, we provide you with the material book (MTC).

The table on the right is the cuni pipe size chart you need. The table has cuni pipe OD wall thickness, and weight for each size.

We have been supplying cuni pipe to our global clients for 20+ years. The table on the right is the most common OD wall thickness you can refer to.

The following video introduces you to the cuni pipes stored in our warehouse.

Huajian maintains a large inventory of CuNi pipes to meet the urgent delivery needs of our shipyard customers. We stock CuNi pipes in grades CuNi 90/10, C70600, and C71500, with outer diameters ranging from 16mm to 508mm, conforming to DIN 86019 and EEMUA 234 standards. Available wall thickness options include 10bar, 14bar, and 16bar.

Unlike other suppliers, we offer a significant advantage with our ready-to-ship inventory, eliminating the typical 50-day lead time required for production. This ensures that our customers receive high-quality CuNi pipes quickly and efficiently, supporting their project timelines with minimal delays.

✅ Over 20 years of experience supplying CuNi pipes for shipyards and offshore platform projects

✅ Each pipe size is tested and traceable by heat number for full batch identification

✅ Certified by major classification societies: CCS, DNV, ABS

✅ Competitive pricing compared to European suppliers

✅ Stock availability in standard DIN 86019 & EEMUA 234 sizes (DN15–DN400)

✅ Fast response and a professional export team ready to support you

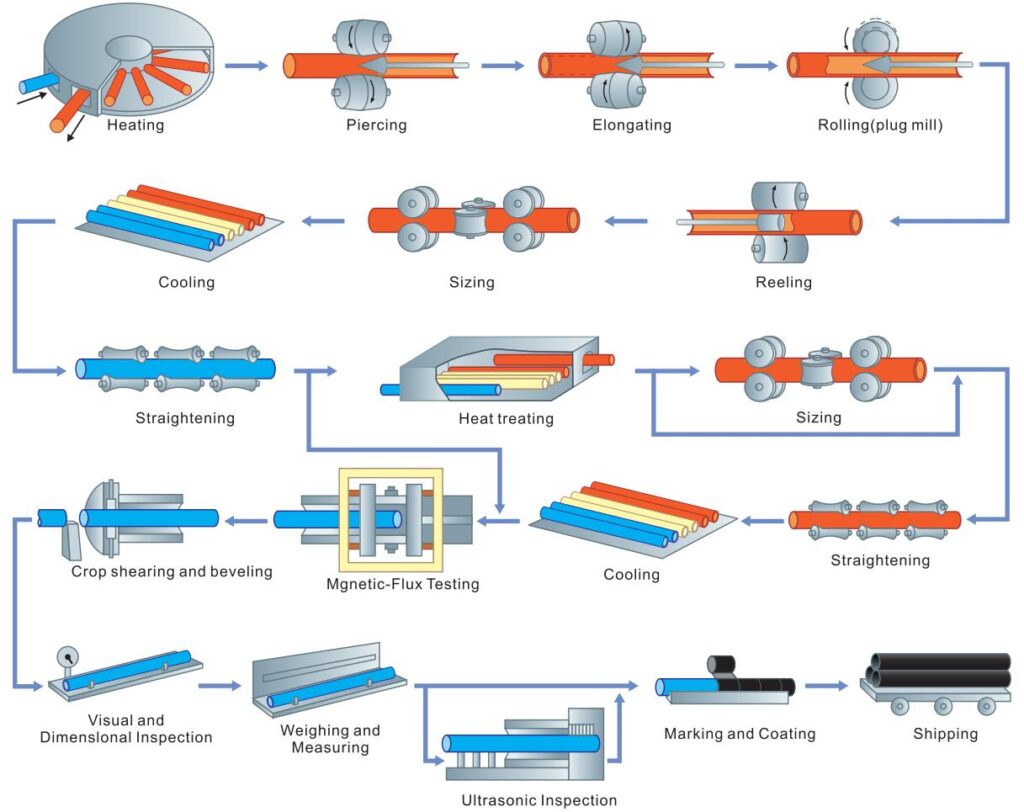

We offer CuNi pipes in grades such as CuNi90/10, CuNi10Fe1.6Mn, and C70600. High-purity electrolytic nickel and copper are melted into billets, which ensure excellent seawater corrosion resistance.

Pipes are cold-extruded into various sizes, then annealed and straightened. Each pipe undergoes eddy current testing, with a test report provided upon delivery.

After passing chemical and mechanical tests, specifications and material grades are clearly marked on each pipe for full traceability.

We quote per kilogram and per meter. You can also quote per cuni pipe, 6 meters per piece. The price of cuni pipes depends on the copper and nickel prices on the day, plus the processing fee.

The price of cuni pipe depends largely on the copper price of the day. You want to buy good price cuni pipe, choose the time when the market price of copper is low.

Chemical composition test: This is the most important. Quality control engineers use the spectrometer to test the Cu, Ni, Fe, and Mn of cuni pipes, the composition is by the standard regulations. Chemical composition does not meet, and it was judged as unqualified products, scrap disposal.

Wall Thickness Test: Engineer will measure the thickness of the cuni pipe with calibrated vernier callipers. The outside diameter of a cuni pipe is less than 4 inches, thickness of the cuni pipe at any point cannot vary more than 10% from the standard specification.

Measured cuni pipe wall thicknesses differing from standard specifications by more than 10 percent are judged unacceptable.

Ellipticity Detection: Measurement of the maximum and minimum diameters of the same section of cuni pipes. The difference between the maximum and minimum diameters must not exceed 2% of the standard.

Copper nickel tubing is 6 meters/pc. Quantity is less than 3 pcs, need to cut into 2 meters/pcs for shipment. Quantity is more than 3 pcs, 6m/pcs are shipped. cuni pipe is shipped in customized plywood crates. cuni pipe is made of very soft material, and sponge pads are put inside the crates to prevent bumping.

The cuni pipe you receive is guaranteed not to be scratched, warped.