I have been in charge of CuNi 90/10 pipe and flange manufacturing and sales for 11 years. Supply cuni90/10 to 200+ customers worldwide markets.

our customers have been asking questions about the cuni 90/10 lately, so I have compiled all the essential knowledge about CuNi90/10. It should help you.

The cuni 90/10 is a copper nickel alloy with 10% nickel, 90% copper,1.6% iron, and 0.5%manganese. Also known as C70600. Resistant to seawater corrosion, seawater pipe selection of cuni90/10 with 20+ years of service life, our user feedback.

CuNi90/10 Used in naval, nuclear power, shipbuilding, and oil & gas offshore platforms.

Below I will describe in detail the features of the cuni 90/10.

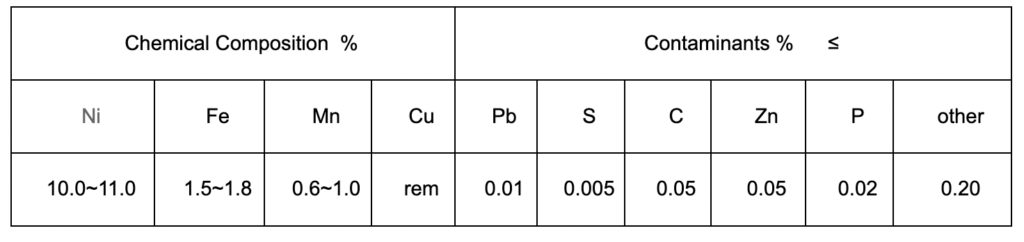

CuNi 90/10 Chemical Composition

You can follow the table below to test the chemical composition of your CuNi 90/10 product for passing. You can use an instrument to test copper, nickel, and iron-manganese elements to determine whether they pass or fail. To measure composition, you can use a handheld spectrometer; it’s easier.

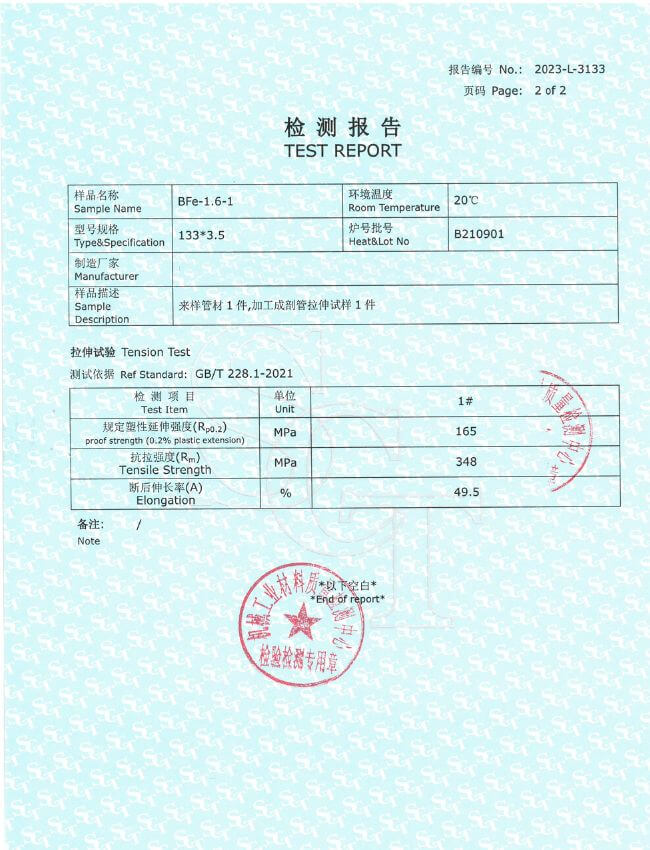

CuNi 90/10 Mechanical Properties

The annealed state of the cuni 90/10 is soft (M), which you need to be aware of. The chart below shows the results of our CuNi90/10 tested at the Institute for Materials Research.

By looking at the tensile strength and elongation, you judge whether cuni90/10 mechanical properties are qualified. Tensile strength ≥ 300N/mm² and elongation ≥ 30 are qualified.

Related Grade Of CuNi 90/10

The cuni 90/10 is called different things in different countries. Here are the grades in different national standards. Each country has a different cuni90 grade with a similar chemical composition. You can instead use it.

- EEMUA 234 UNS C70600

- BS 2871 CN 102

- DIN 86019 2.1972

- EN CuNi10Fe1.6Mn

- MIL-T-16420K ASTM B 466 C70600

- JIS H 3300 C7060T

Processing Method

CuNi90/10 elbow, tee, the reducer is pipe cold processing moulding. cuni90/10 flange is round bar forging moulding that belongs to hot processing. This is a testament to the excellent ductility of the cuni 90/10, worth your choice.

CuNi 90/10 Easily Welded

CuNi90/10 is argon arc welded. The tube inside must be filled with argon or nitrogen when welding. If it doesn’t, you have tiny air holes all over the inside of the weld. Such a weld with a gas hole in the middle will leak over time.

We also undertake welding projects for our customers. Below are pictures of our cuni 90/10 welding for your reference.

Check out this instructional video if you plan on soldering cuni 90/10 tubes.

CuNi 90/10 Density

The density of cuni 90/10 is 8.94 g/cc; you can use it to calculate weight.

CuNi 90/10 Colour

The colour of CuNi is earthy brown, which is specific to CuNi90/10. You can identify CuNi90/10 by its colour to the naked eye. the picture below shows the colour of CuNi 90/10.

CuNi 90/10 Product

CuNi90/10 material is soft, has excellent elongation, and is easy for mechanical moulding processing. Standard products are CuNi90/10 pipes and CuNi Flanges. We are manufacturer of CuNi 90/10 Pipe Fittings. We have 20 years of experience, so you can trust us.

CuNi70/30 , C71500 Material

The cuni 70/30 has a higher nickel content of 30%. It is more resistant to seawater corrosion and harder than cuni90/10. In harsher seawater environments, you can choose cuni70/30.

How Identify CuNi90/10 And CuNi70/30

CuNi 90/10 and cuni 70/30 are two materials with different chemical compositions. You can differentiate between cuni90/10 and cuni70/30 by colour. The picture below shows cuni90/10 on the left and cuni70/30 on the right, with a clear colour difference.

Conclusion

CuNi90/10 lasts as long as the boat or equipment, and you can do without maintenance.CuNi 90/10 has proven excellent resistance to seawater corrosion and is worth choosing for your project. Don’t hesitate to contact me with any questions or want to know more about our cuni 90/10 products.