Copper Nickel Pipes manufacturer in china

Our company is committed to providing CuNi90/10 and CuNi70/30 pipes at a reasonable price.

sales@copperry.com

Our company is committed to providing CuNi90/10 and CuNi70/30 pipes at a reasonable price.

COPPERRY is a supplier of copper nickel pipes in China, established in 1997. Our company is close to Shanghai port, so it is easy to export.COPPERRY has a large stock of copper nickel pipe with complete size and wall thickness.

Copper nickel pipe is also known as CuNi pipe. The main grades are CuNi90/10, CuNii70/30, C70600, C71500.

Copper nickel pipes are often used in seawater piping because of their resistance to seawater corrosion and marine biology.

COPPERRY copper nickel pipes are certified by CCS, ABS and DNV-GL.

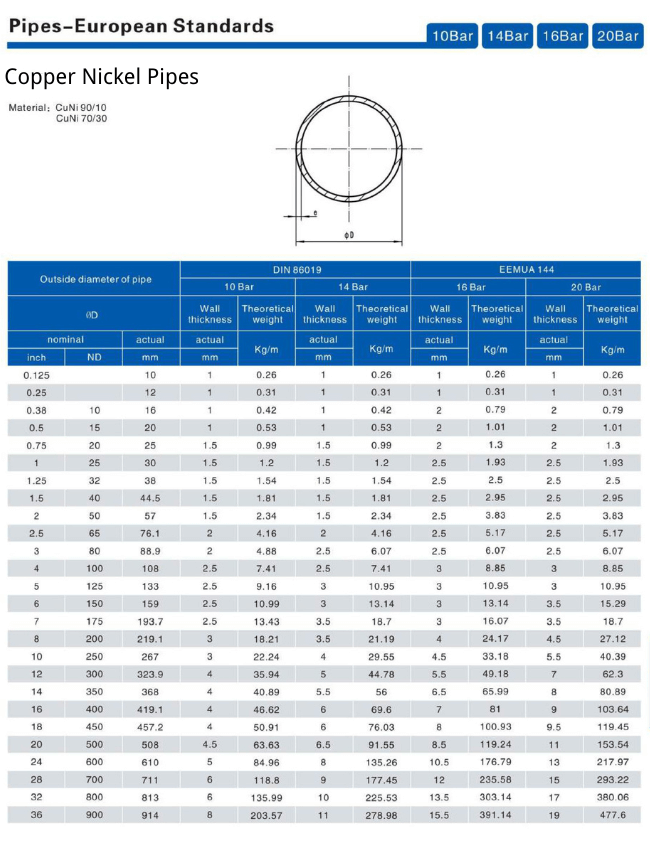

Copper Nickel Pipes Dimensions Chart

Our copper nickel pipes are manufactured according to EEMUA 234 and DIN 86019 standards, ensuring they are of the highest quality. 6 meters per piece. All copper nickel pipes have been tested for chemical composition and physical hardness with satisfactory results. We will provide factory inspection reports upon delivery. To make you trust us, we will take photos and videos of the inspection process and send them to you before we ship.

DIN 86019 pipes

DIN86019 is a German standard. It is to make industry regulations on seamless copper nickel pipes outer diameter wall thickness. The copper nickel pipes used in the shipbuilding industry often adopt this standard.

CuNi Pipes

The grades of cuni pipe are cuni90/10, cuni70/30. CuNi pipe is the simplified form of copper nickel pipe. If you want to know more, you can click learn more below.

C70600 pipes

The chemical composition of C70600 is identical to that of CUNI90/10; they are simply different call names.

CuNi90/10 Pipes (EEMUA 234)

cuni90/10 pipe conforming to EEMUA 234 standard, primarily used in offshore marine engineering. Available in 16 BAR and 20 BAR pressure ratings, with corresponding wall thicknesses different for each pressure level.

Our warehouse has many copper nickel pipes from 20 mm OD to 419 mm OD. If you have copper nickel pipes in a hurry and require them in stock, our large stock can accommodate you. your order, we can ship immediately.

Even if the number of copper nickel is small, we can do it for you.

If the quantity is too small, the copper nickel pipes 6m needs to be cut short for 3 meter/ length delivery.

CuNi90/10 and CuNi/30 pipes, C70600 pipes, and C71500 pipes. We have all these pipes in stock. We can supply them all to you.We regularly produce copper nickel pipes of these types and are experienced in their production.

COPPERRY’s copper-nickel smelting, billet making and copper nickel pipe drawing are all in China. The supply chain has the advantage of being a global leader. These determine that the copper nickel pipes supplied to you are very reasonably priced.

If you have any further questions or need additional information about copper nickel pipes, please contact us.

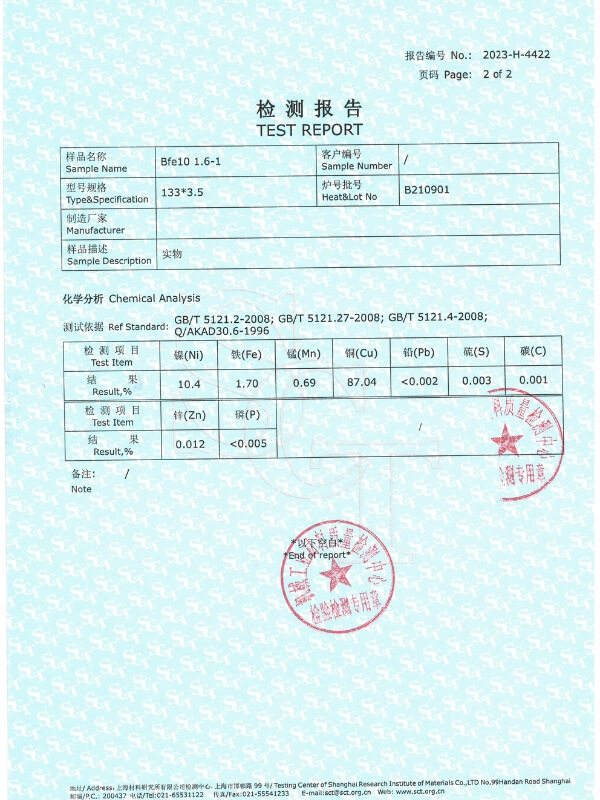

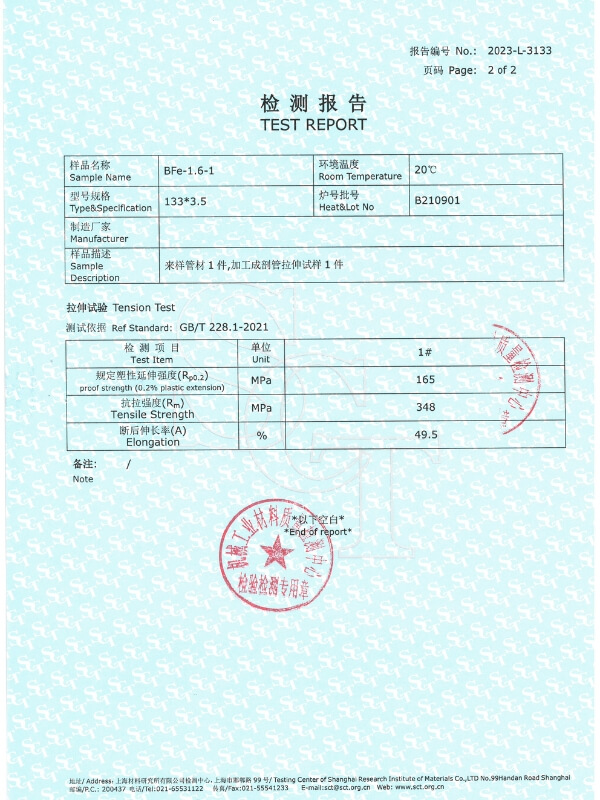

COPPERRY got a third party authority to test the copper nickel pipes. This organisation is the Shanghai Institute for Materials Research, which is the most authoritative non-ferrous metal testing organisation in China.

The picture below is the result of our copper nickel pipe testing.

We saw off a section of copper nickel pipe from the warehouse, and the testing organisation checked the chemical composition. The picture above shows the test results. The chemical composition of COPPERRY copper nickel pipes meets the standard.

We tested the elongation and tensile strength of copper nickel pipes. These two items are the most important for mechanical properties. The above test results elongation is 49.5; the standard specification is ≥ 30, and the test is qualified. The tensile strength test result is 348Mpa; the standard specification is ≥300Mpa, and the test is qualified.

Shipbuilding project for the Thai Navy, Copper nickel pipes supplied by COPPERRY in 2022. We inspect 57*1.5 CuNi 90/10 tube OD and wall thickness before shipment. So we will inspect the copper nickel pipes again before shipment to our customers. The deviation of outer diameter size is ±2%, and the wall thickness deviation is ±5%.

Brazilian oil offshore customer. They need copper-nickel tubes of the European standard EEMUA234. Because of our good service, we gained their trust. They asked the delivery time is 30 days. Because they are very urgent, we prioritise the production of this order.

I started working for this company after college and have been there for 12 years experience. Below are the questions our customers often encounter, we have compiled them, and they will help you.

Below are the dimensions and wall thicknesses of copper nickel pipes for European standards. You can ask the professional us if you have questions about the dimensions.

Chemical Composition % | Contaminants % ≤ | ||||||||

Ni | Fe | Mn | Cu | Pb | S | C | Zn | P | other |

10.0~11.0 | 1.5~1.8 | 0.6~1.0 | rem | 0.01 | 0.005 | 0.05 | 0.02 | 0.02 | 0.20 |

mode | yield strength RP0.2 MPa | tensile strength Rm MPa | Brinell hardness HB | Elongation A% |

M | ≥100 | ≥300 | ≥70 | ≥30 |

copper nickel pipes can be welded using traditional techniques, such as argon arc welding. (ps: the welding process must be protected by argon gas in the tube).

The correct welding procedure must be followed, CuNi 70/30 wire must be used as filler material, and the welder should preferably be experienced.

Copper nickel pipe soldering tutorial you can watch this video.

Copper nickel pipes contain copper and nickel, which are precious metals and expensive on the market.

This is the fundamental reason why copper nickel pipes are expensive.

You think copper nickel pipe is expensive because you are comparing it to stainless steel pipe.

But in seawater, copper nickel pipes are superior to stainless steel tubes in terms of corrosion resistance.

The price of CuNi90/10 pipe can be estimated based on the international market price of copper and nickel for the day (this price is available online). The calculation is 90% of the day’s copper price, plus 10% of the day’s nickel price. To this, the cost of processing is added to give the ex-works price of CuNi90/10 pipe.

Please note that these prices fluctuate and to get the most accurate and up-to-date prices for CuNi pipe, please feel free to contact us. We will be happy to provide you with a detailed quotation.

We can produce seamless CuNi90/10 pipes from OD 20mm to OD 710mm (Larger than 419mm is welded pipe).

We can produce seamless CuNi70/30 pipes from OD 20mm to OD 324mm.

In simple terms, CuNi90/10 fittings have 90% copper and 10% nickel.

While CuNi70/30 fittings have 70% copper and 30% nickel, there is a difference between the two.

Our usual third party testing institute is the Shanghai Institute of Materials Research.

This is the leading materials testing institute in China. This institute can test the chemical composition and mechanical properties of copper nickel pipes and issue a report.

If you are not sure, you can hire QC personnel to carry out the test.

You can tell us when the third party personnel will come to test the copper nickel pipes.

We will be very cooperative with their testing of copper nickel pipes.

Yes, you can bend copper nickel alloy pipes. However, you need to place a mould inside the copper nickel pipe when bending, otherwise, the copper nickel pipe will crack and wrinkle.

Our customers have tried bending copper nickel pipes directly on the bending machine without using a mould or heating the pipe. The result was that the copper nickel pipes would crease when bent. Copper nickel pipes can be bent, but they require a specific mould. It is advisable not to bend them yourself and you should use an elbow where the copper nickel pipe needs to be bent.

After annealing, copper nickel pipes undergo acid pickling and passivation. Following polishing and thorough wiping, a uniform oxide layer will form on the tube surface over time.

The most fundamental test involves verifying whether the chemical composition of copper nickel pipes meets standards. Typically, hardness and elongation are also examined. For more in-depth testing, the metallographic structure of the copper nickel pipes must be analyzed.

Our shipyard client. One end of the copper-nickel pipe was welded to the bulkhead of the ship’s hold, while the other end was welded to a flange and valve connection. After installation, a crack was discovered in the copper-nickel pipe (see image below). This situation has never been encountered by the shipyard before.

Initially, our customers suspected that the issue stemmed from our product quality. Our products undergo rigorous inspection, and we never ship copper-nickel pipes with cracks. Upon investigation, the customer discovered that during installation, the distance between the copper-nickel pipe and the valve was insufficient. As a result, the installation crew forcibly tightened the flange bolts. The copper-nickel pipe has an outer diameter of 44.5mm and a wall thickness of 1.5mm. Its thin wall and relatively soft material led to the pipe being forcibly pulled apart, causing the cracks.

In this situation, the shipyard’s solution is to remove the fractured copper-nickel pipe, re-weld it, and reinstall it. The option of welding over the crack was also considered but rejected because it was deemed unsafe and would not guarantee service life.

You can also email us for a quick response.