Copper Nickel Flanges Manufacturers in China

20 years of producing high-quality CuNi90/10 and CuNi70/30 flanges. Offering competitive pricing and fast delivery.

Certificates:CCS, ISO,DNV-GL

Standards:DIN, EEMUA, EHN,ASME

Size:16mm to 911mm

sales@copperry.com

20 years of producing high-quality CuNi90/10 and CuNi70/30 flanges. Offering competitive pricing and fast delivery.

Certificates:CCS, ISO,DNV-GL

Standards:DIN, EEMUA, EHN,ASME

Size:16mm to 911mm

COPPERRY can produce cuni 90/10 and cuni 70/30 flanges. The copper nickel weld neck flanges, copper nickel loose sleeve flanges, copper nickel slip on flanges, copper nickel inner flanges that you need for your project, we can make them all. Our company has been making copper nickel flanges for more than 20 years. Copper nickel flanges supplied to our customers are used in shipbuilding, chemical, and condensing equipment.Because copper nickel flanges are resistant to seawater corrosion, have a long service life. have any questions please contact us.

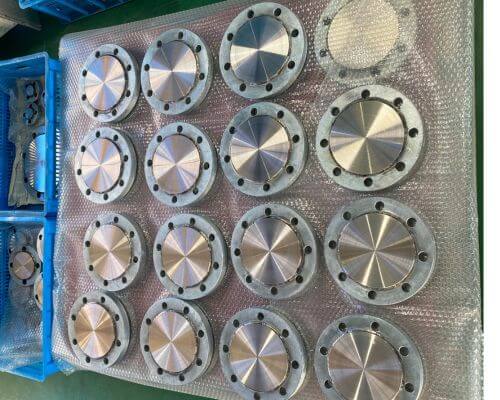

copper nickel composite blind flange

Learn more

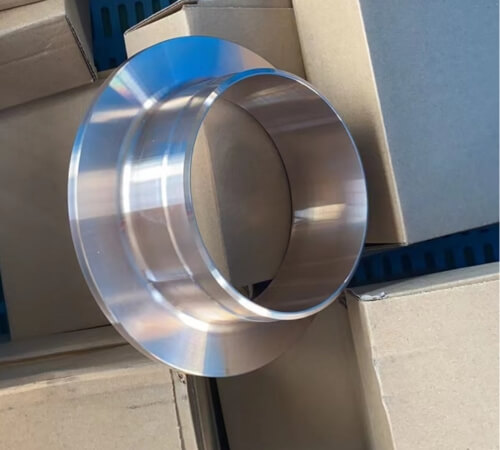

copper nickel long inner flange

Learn more

copper nickel solid slip on flanges

Learn more

COPPERRY have copper nickel round bars in different outer diameter sizes in stock. We receive orders and take raw materials directly from our own warehouse for cutting. meet your requirements for delivery.

We have Φ20mm to Φ 200mm cuni 90/10 and cuni70/30 bars in the warehouse. We can forge the material in one or two days after receiving the order.

Grade cuni90/10, cuni70/30, cuni10fe1.6mn, cuni30fe1.0mn material flanges, we can do it for you.

If you need non-standard copper nickel flanges, we can process them according to the drawings you provide.

We have an advantage in the price of our raw materials. Copper nickel flanges are mass-produced and have a price advantage over other companies.

The following video introduces you to the process of making copper nickel flanges. After watching the video you can trust my manufacturing capabilities.

CNC Machining

We have 10 CNC machines. We can make all forms of copper-nickel flanges. Among them, there are too big machine tools that can process flanges up to 700mm outer diameter.

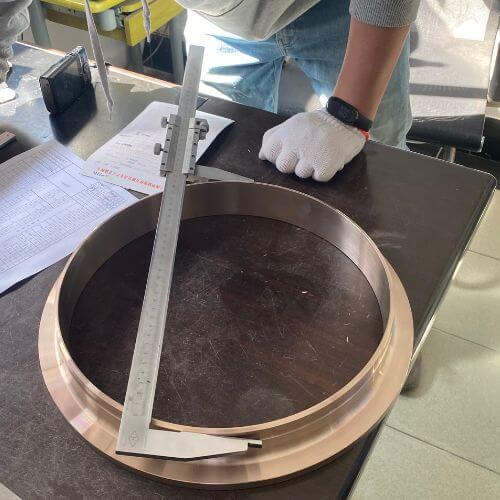

Below is a picture of our inspection of the copper-nickel flange. We measure the chemical composition of the material and the size of the product. We are professional copper nickel flange manufacturer in China. Test the copper-nickel flanges as you requested.

The copper nickel composite blind flange is a 5mm cuni round plate welded to the sealing surface of a hot dip galvanized A105 flange. Contact with seawater is cuni material, both to meet the design requirements, can help you reduce the cost of the project.

The din8037 loose composite flange, copper nickel inner flange and hot dip galvanized outer flange are used together. This is a product we often make for our shipyard customers and it is suitable for you too.

This is the c70600 flange for offshore oil engineering customers. The specifications are 2 inches, 4 inches and 8 inches. The standard is EEMUA234 20Bar.

COPPERRY has manufactured and supplied copper nickel flanges to more than 1,000 customers. Customers are satisfied with the speed of delivery of customised copper-nickel flanges according to drawings. Most of these customers are still working with us and trust us.

Our factory has CCS, DNV-GL, LR, ISO9001 certificates. Passing these certifications indicates that our quality is best.

The maximum size of copper nickel flanges we can do is 710mm because we have special large lathe.

We have supplied copper nickel flanges to more than a dozen countries around the world. We are very familiar with the process of packing goods, delivery to substitute warehouses, sea freight and air freight.

COPPERRY has been making copper nickel flanges for 20 years and understands copper nickel is very soft and easily bruised.

We value the packaging of copper nickel flanges. Copper-nickel flanges are packed in cartons or bubble bags.

After put into the plywood crate, we will also pad cardboard to prevent the copper nickel flanges from moving and collision.

You can choose the packaging without our company name. Of course, it can be packed according to your requirements.

The most commonly used copper nickel flange is EEMUA234. copper nickel flange is tested according to the EEMUA standard. the standard error specifies that the hole center distance is +0.9mm, and the diameter of the bolt hole measures +0.5mm. we use a spectrometer to test the copper nickel flange chemical composition to see if it complies with the standard.

Our Email is sales@copperry.com