Copper Nickel Elbow Manufacturer In china

- full range of materials,CuNi90/10,CuNi70/30,C70600,C71500.

- No minimum order limit

- In stock for quick shipment.

- 20 years of industry experience and reliable quality.

sales@copperry.com

Copper Nickel Elbow Manufacturer In china

Oversized copper nickel elbows are difficult to make, most manufacturers are unable to make them. We have already made copper nickel elbows such as 508mm and 610mm for our customers, our technology is mature. Customers are very satisfied with our products.

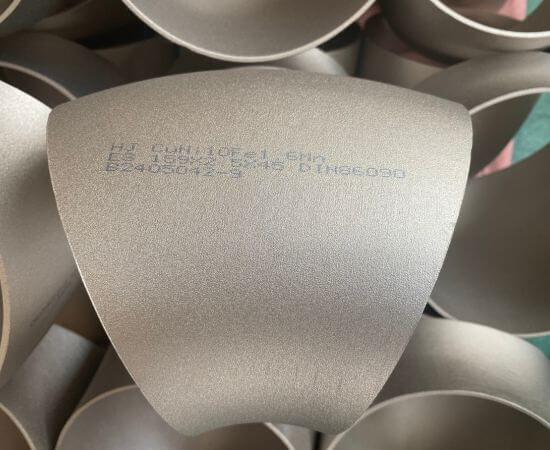

The welding method is butt welding. The surface is sandblasted. Standards is EEMUA234, EHN9511,DIN86090.

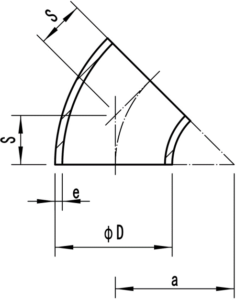

We can make short 45 degree elbows according to the standard.

Elbow ends are socket welded. Made from forged copper nickel bar. Standard is ASME B16.5 and EEMUA234.

Copper nickel butt weld elbows in stock and ready to ship. The workshop workers are all experienced in producing copper nickel elbows for 15 years. The video below shows the production process of copper-nickel elbows.

At COPPERRY, copper nickel elbows are CCS, DNV-GL, LR, BV approved. This shows that the quality of our elbows meets your project requirements.

Our engineers have been researching and designing copper-nickel elbows for 12 years. Familiar with every copper nickel elbow standard, we can solve your project problems quickly and professionally.

The picture below shows corner of our inventory. We have large inventory of copper nickel elbows. Copper nickel elbows you need for your project can be sent directly from our warehouse.

The raw materials of copper-nickel elbow are strictly inspected. Sampling tests are also carried out during production and on finished products. Copper-nickel elbows are supplied with certificate EN 10204 3.1 and fumigation certificates ISPM15

COPPERRY’s cuni elbows are recognized by classification societies worldwide. You trust the quality of our products.

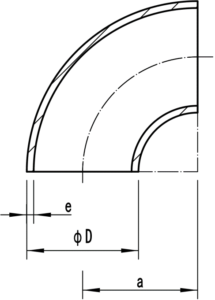

Below copper nickel elbow sizes for you to choose.

Outside diameter of pipe | DIN86090 | ||||||||

10Bar | 14Bar | ||||||||

ΦD | thickness | radius | weight | thickness | radius | weight | |||

nominal | actual | e | a | s | e | a | s | ||

inch | mm | mm | mm | mm | kg/pcs | mm | mm | mm | kg/pcs |

1 | 30 | 1.5 | 30 | 12 | 0.02 | 1.5 | 30 | 12 | 0.02 |

1.25 | 38 | 1.5 | 32.5 | 14 | 0.04 | 1.5 | 32.5 | 14 | 0.04 |

1.5 | 44.5 | 1.5 | 40 | 17 | 0.06 | 1.5 | 40 | 17 | 0.06 |

2 | 57 | 1.5 | 52.5 | 22 | 0.1 | 1.5 | 52.5 | 22 | 0.1 |

2.5 | 76.1 | 2 | 70 | 29 | 0.22 | 2 | 70 | 29 | 0. 22 |

3 | 88.9 | 2 | 82.5 | 34 | 0.32 | 2.5 | 82.5 | 34 | 0.4 |

4 | 108 | 2.5 | 100 | 41 | 0.58 | 2.5 | 100 | 41 | 0.58 |

5 | 133 | 2.5 | 125 | 52 | 0.9 | 3 | 125 | 52 | 1.08 |

6 | 159 | 2.5 | 150 | 62 | 1.3 | 3 | 150 | 62 | 1.56 |

8 | 219.1 | 3 | 210 | 87 | 3 | 4.5 | 210 | 87 | 3.5 |

10 | 267 | 3 | 255 | 106 | 4.4 | 4 | 255 | 106 | 5.87 |

12 | 323. 9 | 4 | 305 | 126 | 8.6 | 5 | 305 | 126 | 10. 75 |

14 | 368 | 4 | 352.5 | 146 | 11.3 | 5.5 | 352.5 | 146 | 15.54 |

16 | 419.1 | 4 | 400 | 166 | 16.4 | 6 | 400 | 166 | 21.87 |

18 | 457.2 | 4 | 455 | 188 | 20.4 | 6 | 455 | 188 | 30.6 |

20 | 508 | 4.5 | 505 | 209 | 28.1 | 6. 6 | 505 | 209 | 42.15 |

24 | 610 | 5 | 610 | 253 | 40.9 | 8 | 610 | 258 | 65.45 |

Outside diameter of pipe | DIN86090 | ||||||||

10Bar | 14Bar | ||||||||

ΦD | thickness | radius | weight | thickness | radius | weight | |||

nominal | actual | e | a | e | a | ||||

inch | mm | mm | mm | kg/pcs | mm | mm | kg/pcs | ||

1 | 30 | 1.5 | 30 | 0 | 1.5 | 30 | 0.04 | ||

1.25 | 38 | 1.5 | 33 | 0.08 | 1.5 | 32.5 | 0.08 | ||

1.5 | 44.5 | 1.5 | 40 | 0.12 | 1.5 | 40 | 0.12 | ||

2 | 57 | 1.5 | 52.5 | 0.2 | 1.5 | 52.5 | 0.2 | ||

2.5 | 76 1 | 1.5 | 70 | 0. 44 | 1.5 | 70 | 0. 44 | ||

3 | 88.9 | 2 | 82.5 | 0.64 | 3. 5 | 82.5 | 0.8 | ||

4 | 108 | 2.5 | 100 | 1.16 | 2.5 | 10 0 | 1.16 | ||

5 | 133 | 2.5 | 125 | 1.8 | 3 | 125 | 2.16 | ||

6 | 15 9 | 2.5 | 150 | 2.6 | 3 | 150 | 3.1 2 | ||

8 | 219.1 | 3 | 210 | 3.8 | 3.5 | 210 | 7 | ||

10 | 267 | 3 | 255 | 8.8 | 4 | 255 | 11.74 | ||

12 | 323. 9 | 4 | 305 | 17.2 | 5 | 305 | 21.5 | ||

14 | 368 | 4 | 353 | 22.6 | 5.5 | 352.5 | 31.08 | ||

16 | 419 | 4 | 400 | 32.8 | 6 | 400 | 43.74 | ||

18 | 457.2 | 4 | 455 | 40.8 | 6 | 455 | 61.2 | ||

20 | 508 | 4.5 | 505 | 56.2 | 6.5 | 505 | 84.3 | ||

24 | 610 | 5 | 610 | 81.8 | 8 | 610 | 130.9 | ||

DIN86090 | ||||||

DN | actual(mm) | S(mm) | Long radius(1.5D) | |||

a(mm) | e(mm) | weight(Kg) | ||||

45° | 90° | |||||

15 | 20 | 1.0 | 25 | 10.4 | 0.01 | 0.02 |

20 | 25 | 1.5 | 27.5 | 11.4 | 0.02 | 0.04 |

25 | 30 | 1.5 | 33.5 | 14 | 0.03 | 0.06 |

32 | 38 | 1.5 | 45 | 19 | 0.05 | 0.1 |

40 | 44.5 | 1.5 | 51 | 21 | 0.07 | 0.14 |

50 | 57 | 1.5 | 72 | 30 | 0.13 | 0.26 |

65 | 76 | 2.0 | 95 | 39 | 0.3 | 0.61 |

80 | 89 | 2.0 | 114.5 | 47 | 0.43 | 0.87 |

100 | 108 | 2.5 | 142.5 | 59 | 0.82 | 1.64 |

125 | 133 | 2.5 | 181 | 75 | 1.29 | 2.58 |

150 | 159 | 2.5 | 216 | 89 | 1.85 | 3.7 |

200 | 219 | 3.0 | 305 | 126 | 4.33 | 8.66 |

250 | 267 | 3.0 | 378 | 157 | 6.55 | 13.1 |

300 | 324 | 4.0 | 457 | 189 | 12.8 | 25.61 |

350 | 368 | 4.0 | 533.5 | 221 | 17 | 34 |

400 | 419 | 4.0 | 609.5 | 252 | 29.9 | 39.4 |

450 | 457 | 4.5 | 686 | 284 | 30.7 | 48.4 |

500 | 508 | 5.0 | 762 | 316 | 41.9 | 75.62 |

| COPPERRY | DIN | EN | BS | EEMUA | ASTM | NF |

CuNi90/10 | 2.1972 | CW 352H | CN 102 | UNS 7060x | C 70600 | CuNi10Fe1Mn |

Copper nickel elbows wall thickness larger than 2.5mm need to be beveled. Copper nickel elbow wall thickness less than or equal 2.5mm not require beveling.

The thickness of both the end and bend of the copper-nickel elbow meets DIN86090 and EEMUA234 standard. You need 89*2.5 elbow, we undercut the pipe is 89*3.

Undercut pipe wall thickness is thickened by 0.5mm, because the elbow wall thickness will be thinned when bending.

The process of our copper nickel elbow bending is internal steel ball push. Outside plus the mold, multiple push bending molding. This process has a low amount of thinning, and does not cause damage to the mechanical properties of the pipe.

The copper nickel elbow can also be made into 15 degree, 30 degree, 60 degree.

The first thing is how many degrees of elbow, followed a short elbow or a long elbow.