sales@copperry.com

Twenty years of experience c70600 flanges manufacturer, providing professional service and products for you!

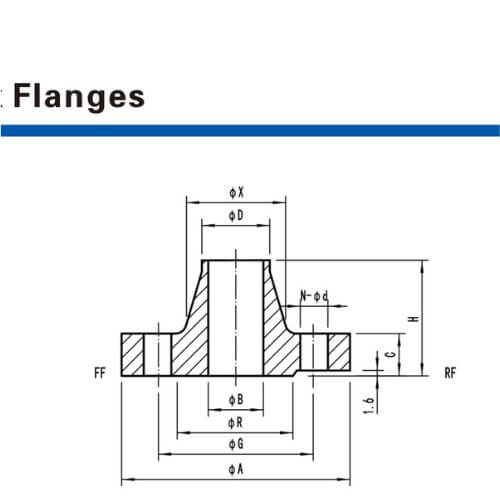

We have been producing c70600 in our factory for 20 years.C70600 flange,Also known as CuNi90/10 flange. types are WN, SW, BL, and LAP. The following are the six commonly used ways, and you can also send us the c70600 flange drawings to make according to your drawings.

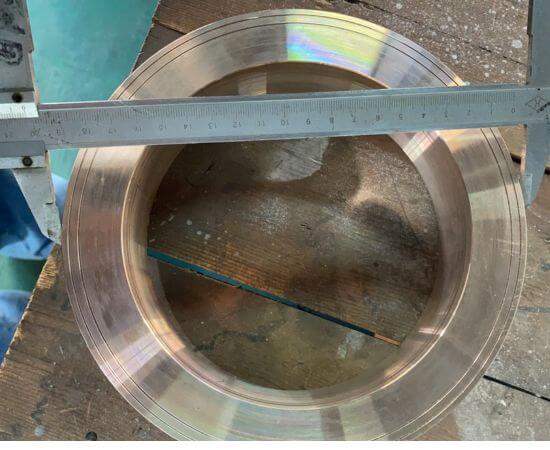

It must be emphasized that to ensure quality, our C70600 flanges are all produced by forging copper-nickel rods.We never produce C70600 flanges using casting methods.

c70600 flange, high neck butt weld, 2 inch, 20 bar, standard eemua234

c70600 blind flange, standard ASME B16.5-2000,150lbs, for offshore oil engineering customers.

C70600 flange, 1/2 inch, socket welded, standardized to EEMUA234.

C70600 inner flange is designed for use with galvanized steel flanges.

C70600 slip on flange, commonly conforming to DIN 86033 standard, using butt welding method.

The C70600 stub end is also designed for use with galvanized outer flanges. The stub end functions similarly to an inner flange when paired with galvanized steel flanges, with the inner flange height being approximately twice that of the stub end.

Things we need to confirm with you before c70600 flange making . Make sure the c70600 flange you receive is accurate.

c70600 flange sealing surface, the standard is no waterline. To quickly fix the sealing gasket when using, some customers require the flange sealing surface waterline to be made into two grooves or dense threads. We can make the waterline according to your request.

You need to provide what standards and pressures the c70600 flanges are according to, as there are many standards for c70600 flanges. If you don’t know what standard, you can send us a screenshot of the drawing. Our experienced technical engineers draw drawings for you to confirm.

You have to tell us what size pipe the c70600 flange is welded to, and we make the neck of the flange to match the wall thickness of the pipe. This makes it easier for you to weld and the welds look better.

The client’s tugboat required c70600 flanges, and we were experienced in welding and undertook the entire copper-nickel pipe welding and testing.

Fire equipment seawater pipes use c70600 flanges, which we are also required to weld well.

c70600 flange is also called CuNi90/10 flange, or CuNi10Fe1.6Mn flange.

We have been manufacturing and supplying flanges to our customers for 20 years. Based on our experience, the standard numbers for C70600 flanges include:

DIN 86037, DIN 86033

EEMUA 234

EN 1092-1

ANSI B16.5

We can also custom-produce flanges according to drawings you provide.

We supply C70600 flanges to shipyards and offshore engineering projects worldwide. Since our company’s inception, we have exclusively provided forged flanges to our customers. Cast C70600 flanges may develop internal defects that lead to leakage during use. Rest assured, our C70600 flanges are forged, eliminating inherent material flaws through the forging process.

According to standards, German standards specify pressure ratings of 10 bar and 14 bar. European standards use pressure ratings of 16 bar and 20 bar, while American standards employ 150 lbs and 300 lbs. The higher the pressure rating, the greater the thickness of the C70600 flange.

We can manufacture flanges ranging in size from 15mm to 910mm. The largest size we have produced for a customer is 711mm.

Due to the numerous standards and dimensions for C70600 flanges, we are unable to maintain stock. For standard C70600 flanges, production takes 15 to 35 days based on specifications, with delivery times dependent on your quantity and requirements. For non-standard C70600 flanges, we require drawings and confirmation through communication with you. This confirmation process takes 3 to 7 days, potentially longer. Therefore, the delivery timeframe for non-standard flanges is 30 to 45 days.

Yes, we can supply you with matching C70600 pipes, elbows, tees, reducers, and other fittings.